ZYB-20M PEEK

The product is based on high-quality low-carbon steel plate, with a porous bronze layer sintered in the middle, and a layer of PEEK and PTFE mixture on the surface. Products are used in automobile chassis, forging machine tools, metallurgical machinery and mines, water conservancy industry, steel rolling industry, etc. Designed to be used in medium and high load conditions under boundary lubrication conditions, the surface oil pockets play a role in storing grease or foreign objects; the use temperature range of the surface resin layer is -150℃~+250℃, which is higher than other thermoplastic materials Temperature resistance grade and better chemical stability at the same time. The initial lubrication can quickly establish an oil film, and the process oil can greatly extend the service life. ZYB-20M is designed with a resin layer thickness of 0.1-0.2mm without oil holes on the surface, and can be processed again after pressing.

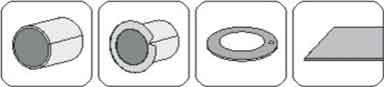

可供形式

Use parameters

| Material and bearing characteristics | unit | value | unit | value |

| Maximum static load | MPa | 250 | psi | 36,000 |

| Maximum dynamic load | MPa | 180 | psi | 26,000 |

| Operating temperature | °C | -60 to 250 | °F | -76 to 482 |

| Dry friction | ||||

| Maximum linear speed | m/s | 2.5 | fpm | 500 |

| Maximum PV value | m/s x MPa | 2.8 | psi x fpm | 80,000 |

| Oil lubrication | ||||

| Maximum linear speed | m/s | 10.0 | fpm | 2000 |

| Maximum PV value | m/s x MPa | 30.0 | psi x fpm | 858,000 |

Product parameter.pdf

Product parameter.pdf